Product Overview

Application Range from 4″ up to 120″ Pipe Diameter

The Rausch Premium enables transmission in Full HD with a resolution of 1920×1080 pixels using copper cables instead of optical fibers. This is possible due to specially developed and patented VML technology. The result: improved quality of the inspection data and reduced running cost based on simplified services requirements.

Technology in the Studio

- Digital CCTV technology in Full HD quality 1920 x 1080 pixel or MPEG4 with 720 x 576 pixel

- Ergonomic operating concept with electrically adjustable desk a for fatigue free working environment

- System control with industrial PC including a 15“ touch screen and two multifunctional joysticks to control the camera and crawler

- User adjustable surface and joystick control

- Digital overlay technology to display readings and data in various country versions

- Display technology and adjustable text size and color

- 22“CCTV monitor in Full HD

- Serial bus system for the control of cable drums, crawlers, cameras and the Full HD Satellite System

- Ethernet connection for video and data exchange including a documentation PC and software

- Alternative recording in MPEG4 format is possible in case Full HD data quantities cannot be processed

System Highlights

- Rear area fittings with passage way to the studio

- Cable drum ELKA 600 HD including observation monitor, telescopic swivel arm and chain winch, cable length up to 1,640 ft

- Cable drum Quadtro SAT HD, cable length 525 ft, push cable 130ft

- Satellite system for the inspection of laterals in Full HD

Rear Area

- Signature spray on flooring

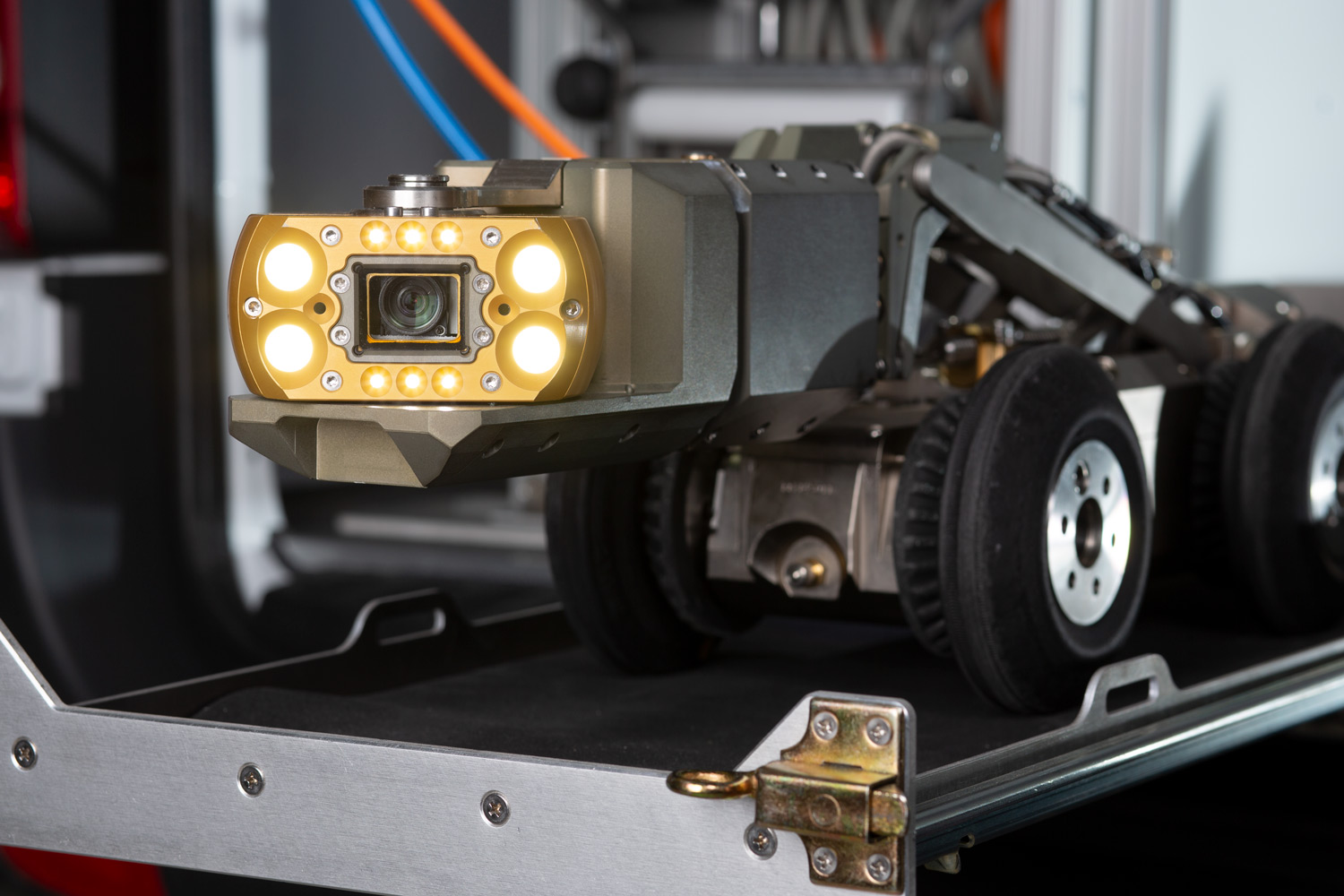

- Expansion with high-quality aluminum profiles and drawers for crawlers and accessories

- Integrated LED lights

- Fully automatic cable drum Elka 600 with integrated 8″ LCD monitor

- Telescopic swivel arm with chain hoist and LED work light

- Satellite cable drum Quadtro SAT

- Pressure monitoring system Premus 600

- 15 Gallon Standard Washdown System

Options

- Deformation measuring

- Software for laser-guided defect measurement

- LATRAS for lateral tracking

- Satellite system for the inspection of laterals

- Pressure tests for leak testing of joints, pipe sections, branches and laterals

- For pipes up to 120 inches in connection with the crawler C 135 and height extension or on a float

- Air conditioning (roof top) with generator application

- Rear canopy

- Additional safety lighting

- Additional rear 19” monitor

- Bathroom

- Sink

- UV Sanitation light

- Solar power

In Depth Look at Components

The Rausch Premium enables transmission in Full HD with a resolution of 1920×1080 pixels using copper cables instead of optical fibers. This is possible due to specially developed and patented VML technology.

Rausch Premium Studio Control

Our powerful video inspection workstation studio

- Digital CCTV technology in Full HD quality 1920 x 1080 pixels or MPEG4 with 720 x 576 pixels

- Ergonomic operating concept with desk for fatigue free working environment

- System control with industrial PC including a 15” touch screen and two multi-functional joysticks to control the camera and crawler

- User adjustable surface and joystick control

- Digital overlay technology to display readings and data in various country versions

- Display technology and adjustable text size and color

- 22” CCTV monitor in Full HD

- Serial bus system for the control of cable drums, crawlers, cameras and the Full HD Satellite System

- Ethernet connection for video and data exchange including a documentation PC and software

- Alternative recording in MPEG4 format is possible in case Full HD data quantities cannot be processed

- Available as Full HD version or as a system “Full HD prepared” for later upgrade

Elka 600 HD Motorized Cable Reel

With up to 1,640 feet of mainline HD copper cable

- Telescopic swivel crane arm

- Electric chain hoist

- Electronic brake and cross-lead spindle for cable winding with cable slack detection

- Slip ring connection for rapid cable change

- Fully synchronized to the camera/crawler unit

- Synchonizes with the Quadtro SAT HD (cable length: 525 ft., push cable: 130 ft.) for lateral launch inspection in Full HD

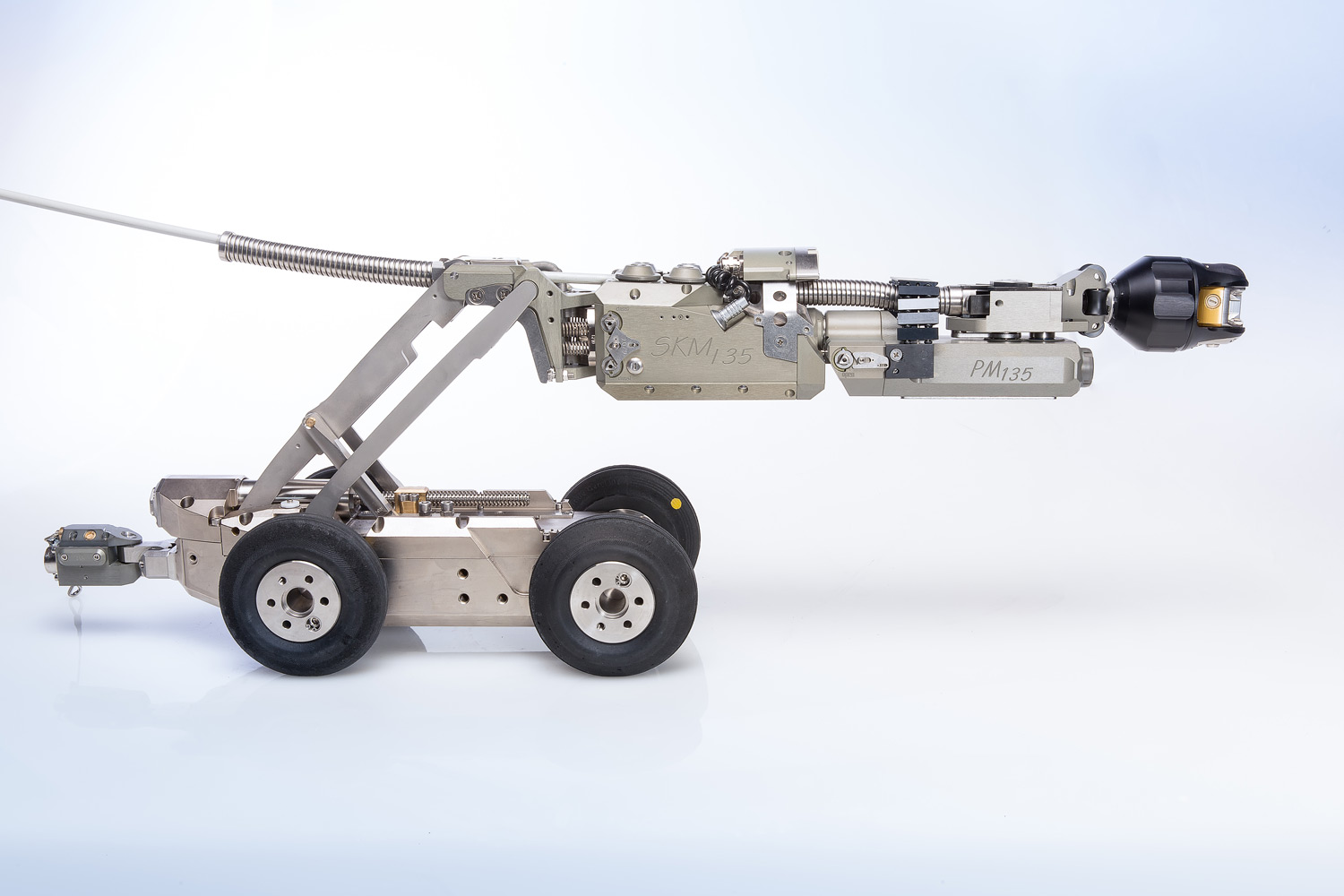

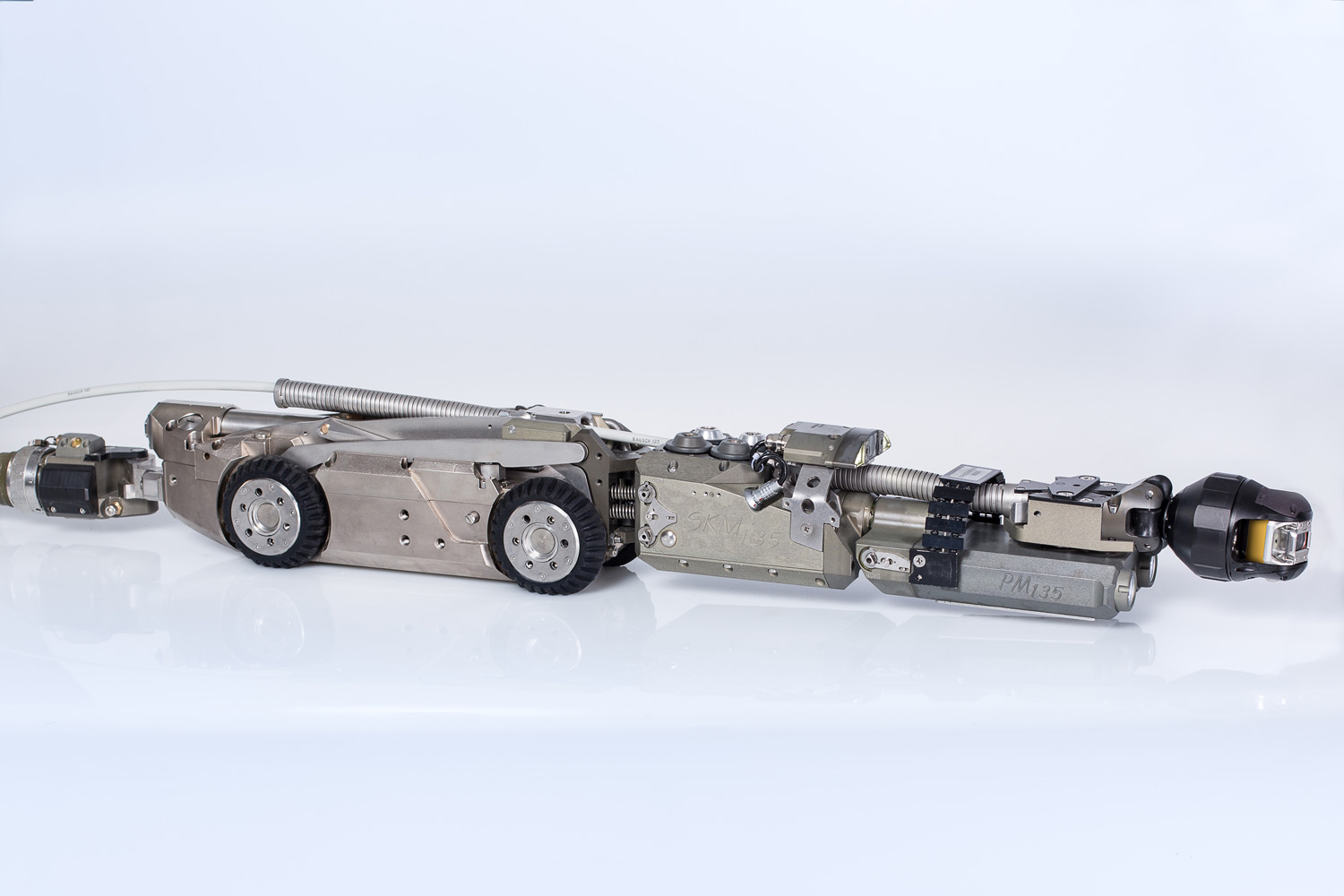

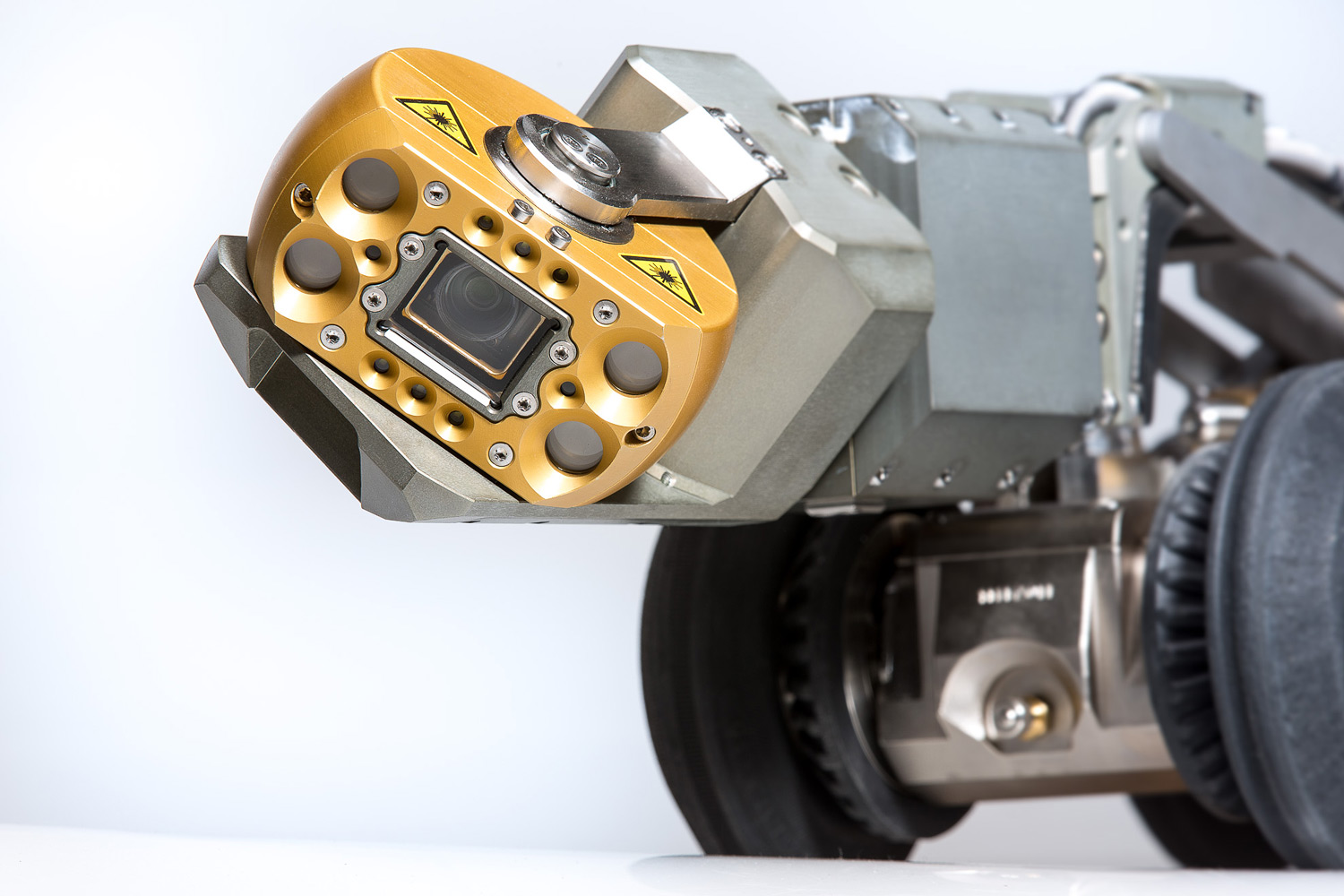

C 135 + KS 135 Scan HD

6″-120″ pipe diameter

C 135 Crawler

- Steerable 4-wheel drive

- Electric lift with reverse camera

- Dual axis inclination sensor*

- Reverse sensor synchronized with cable reel

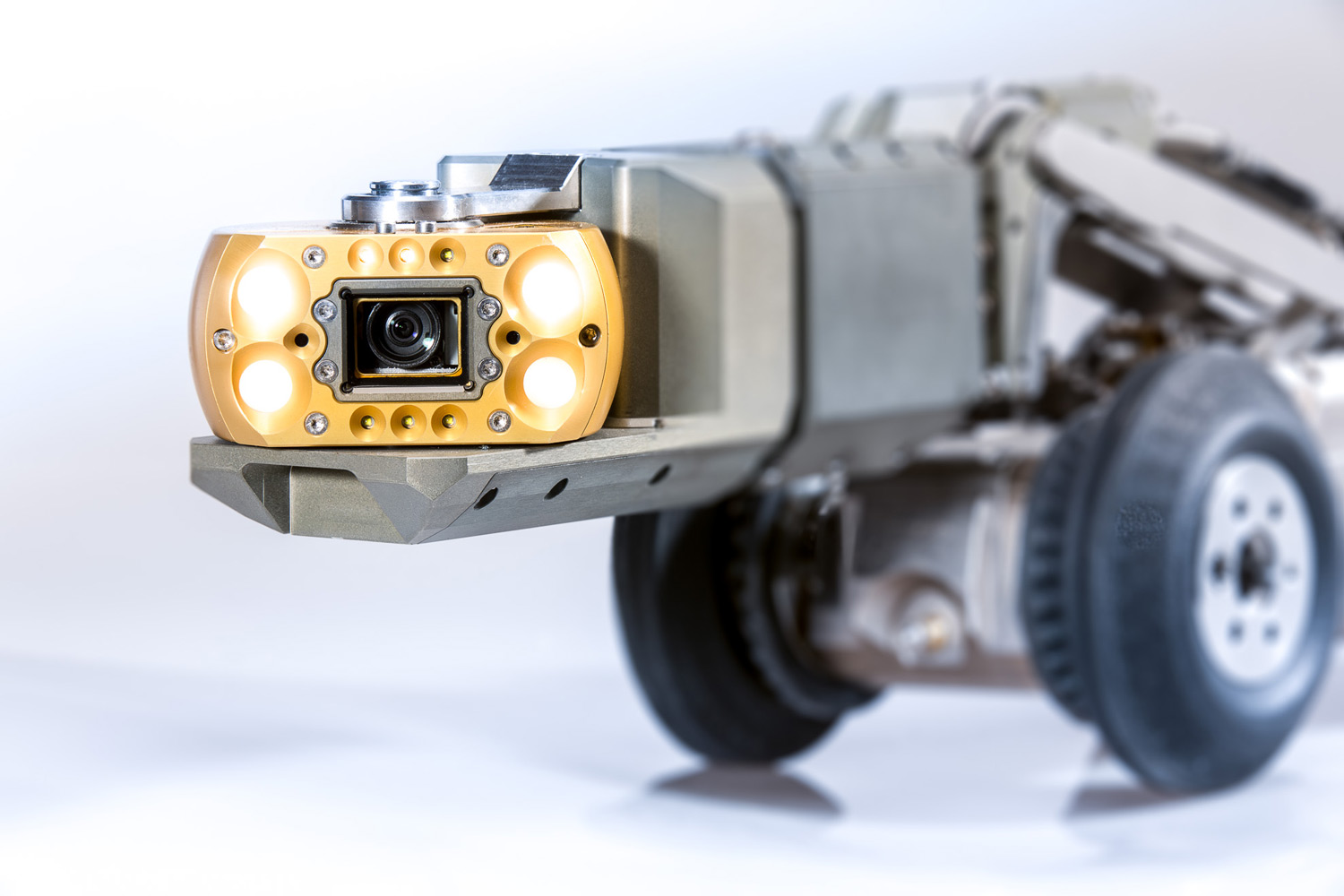

KS 135 C Camera

- 280° pan, infinite 360° rotation

- 10X optical zoom

- Manual & auto focus control

- Four long-range LEDs and 6 short-range LEDs

- 1080p Full HD

- Deformation measurement*

- Laser crack measurement*

Lateral Launch HD

6″- 48″ pipe diameter

M135 System

- Scalable lateral launch system

- Connects directly to electric lift of C135

- Up to 550 ft. cable & 130 ft. push cable

- Synchronized with main cable reel

- Can be upgraded with LATRAS module

KS 60 HD Camera

- Pan and tilt camera with infinite rotation

- Dual camera zoom

- Manual & auto focus control

- Distortion-free wide angle lens

- 1080p Full HD image and video

Request a Quote

Interested? Contact us for a fast, hassle free quote.