Product Overview

Sleeve Sizes are Available from 6″ to 32″ in Circular Pipe Diameter

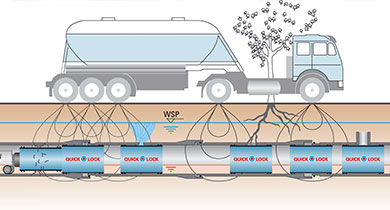

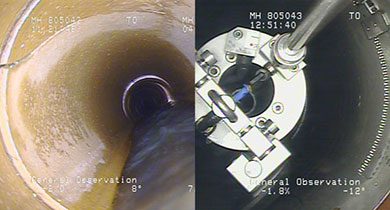

QuickLock is a strictly mechanical point repair system for the inside repair of pipes. No resin is involved. This revolutionary system consists of only (2) components: a 316L stainless steel sleeve structural body, covered by a seamless EPDM compression seal. Through the manhole the sleeve is inserted into the pipe and placed over the damaged section. Using an inflatable packer, the sleeve is then expanded and permanently locked into position.

Application For:

- Municipal sewage lines

- Well and potable water piping systems

- Leaking and/or offset joints

- Root intrusion

- Holes, longitudinal & circumferential cracks

- Abandon laterals

- Restore structural integrity of pipe prior to lining

- Meets ASTM F3110-14 Standard

Not Applicable For:

- Fixing collapsing pipes

- Pipes with an inner pipe pressure above 220psi*

- Industrial sewage (except when corrosion levels have been inspected)

*The precondition for a long-term sealing of pressure pipes is there must be a diffusion resistant inner surface of the pipe. QuickLock installations larger than 16″ in diameter are only proven to withstand internal pressure up to 145psi.

Efficient Solutions

Installation is quick and easy while ensuring a permanent fix. QuickLock sleeves can be installed with flow present due to the fact that the packer is hollow; allowing for the flow pass through. The installation packer can even be attached to most tractor brands currently on the market. The reduction in diameter is minimal. NSF/ANSI Standard 61 Certified for potable water.

Advantages

- Trenchless no-dig spot repair

- Permanent, reliable, and instant fix

- Passes air & water pressure testing.

- Reinstates structural strength & integrity of deformed and damaged pipe.

- Can be installed with flow present.

- Easy and quick installation – no cure time.

- Applicable for internal pressure up to 220 psi*

Installation Process

- Determine if correct application for QuickLock.

- Determine exact pipe ID.

- Determine damage length.

- Prepare the QuickLock sleeve.

- Load the sleeve on the QuickLock Packer.

- Deliver the QuickLock sleeve to the installation.

- Inflate the Packer to install the sleeve.

Required Materials & Tools

- Sharp knife

- Talcum powder

- Super glue

- Biodegradable penetrating oil or food-grade lubricant

- Air hose

- Air compressor

- QuickLock Packer

Extra Tools

- Hydrophilic Waterstop – Where there is heavy groundwater infiltration and the pipe has a rough surface structure, we recommend using an additional hydrophilic waterstop affixed to the rubber gasket to ensure a tight seal.

- Flexible Mortar/Grout Material – When there is existing root penetration, apply this material to the outside of the rubber gasket to prevent roots from growing and penetrating the rubber.

316L Stainless Steel Sleeve

The QuickLock sleeve body is made of 316L stainless steel, SAE Steel Grade. The sleeve maintains high corrosion resistance, meaning it functions in sewage water as well as potable water. This sleeve will reinstate the structural integrity, and working in conjunction with the beveled end creates a new interior for the pipe with a smooth flow. QuickLock is NSF/ANSI 61 Certified for potable water.

EPDM Rubber Gasket

The vulcanized EPDM rubber gasket is the component that actually seals. EPDM distinguishes itself by excellent physical properties and resistance against aging, ozone, atmospheric conditions and environmental influences, alkaline and various bleaches and chemicals. Different gasket materials are available for individual environmental conditions.*

QuickLock Packer

The QuickLock Packer is attached to a trolley and can be mounted to a pipe inspection crawler that guides the system through the line. This specially designed packer provides uniform expansion pressure throughout the overall sleeve length, thus ensuring that the gears run simultaneously during the installation process. Various packer sizes cover a different installation diameter range. For each nominal pipe diameter, there is a suitable set of wheels.

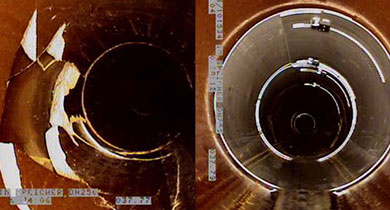

Locking Gear Mechanism

Two saw-tooth channels are punched into the left and right side of the sleeve. In each channel, there is a locking and gear mechanism, guiding the sleeve sheet while being installed. Using the packer to expand the sleeve, the gear works like a one-way ratchet. Upon reaching maximum compression pressure, both gears lock into place and stay locked permanently.

The distance between tooth groove and tooth tip is one click. That means the maximum possible return stroke from tooth tip to the next lower groove may cause a maximum diameter reduction after compression of only about 0.025 inch, independent of the nominal size. Therefore, the locking mechanism operates in an almost infinitely-variable way.

Stainless Steel Sleeve

- Beveled End: The beveled end faces the direction of flow and improves the hydrodynamics, prevents solids from depositing, and increases jetting resistance.

- Metal Overlap: The steel sleeve is rolled up smaller than its nominal diameter. The overlap is what is left over for expanding to the pipe wall.

- Toothed Strip

- Locking Gear

- Adhesive Tape: The tapes are put on at the factory to protect the sleeve during the transport and prevent it from unrolling.

Rubber Gasket

- Circumferential Seals: The actual seal is formed by the circumferential seals compressed against the host pipe. The damaged section must always be between these seals.

- Trimming Line: There is a trimming line marked in the rubber gasket. It shows you where to cut off the projecting rubber end (when a single sleeve is installed).

- Projecting Rubber End: The projecting rubber end acts as a seals between sleeves installed in a series.

Request a QuickLock Quote

Interested? Contact us for a fast, hassle free quote.