Product Overview

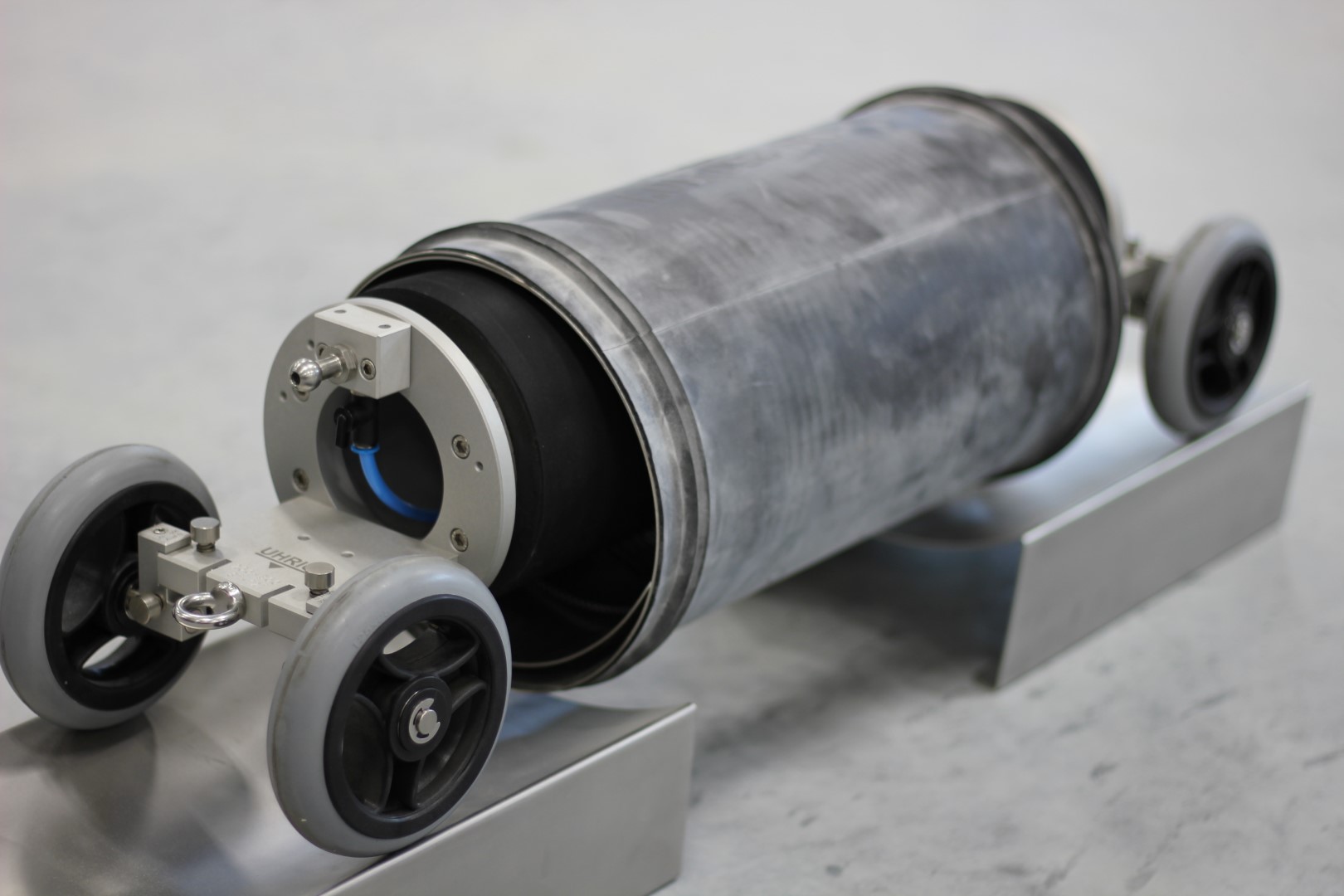

The QuickLock Flex Sleeve is a no-dig point repair system for repairing joint offsets or axial bending inside the pipe. The sleeve features a corrugated steel core with two short 316L QuickLock sleeves on either end with the trademark locking mechanism. The entire sleeve is encased in an EPDM rubber gasket to create a seal against the inside pipe wall.

Application For:

- Correcting joint offsets up to 1″ (2.5cm)

- Correcting axial bending

The QuickLock Flex sleeve is available in nominal diameters of 8″ to 24″ and in the following lengths: 14″ (8″ – 16″ diameter) & 18″ (18″ – 24″ diameter).

Operating Principle

The sleeve body is of 316L stainless steel with a flexible corrugated steel core, covered by an EPDM rubber gasket designed to seal against the pipe wall. The system works strictly on mechanical compression – no resin or grout is involved. The sleeve is expanded by a specially designed packer and locks into place by the one-way ratchet locking gear mechanism.

Advantages

- The Flex can seal the offset joint with a secure connection on both sides of the joint.

- The Flex can repair offset joints without milling or other prep work.

- The corrugated steel core provides a continuous protection of the EPDM seal.

- Passes air & water pressure testing.

- Reinstates structural strength & integrity of deformed anddamaged pipe.

- Can be installed with flow present.

- Easy and quickinstallation – no cure time.

Request a QuickLock Quote

Interested? Contact us for a fast, hassle free quote.